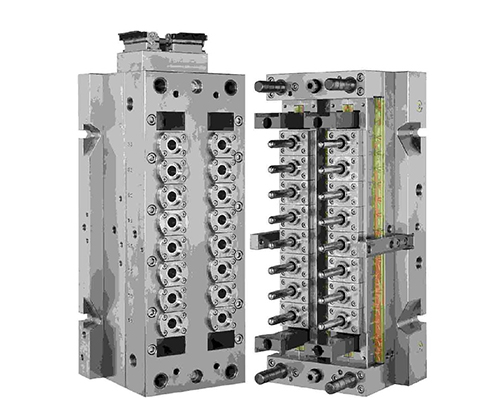

● Among our daily necessities, plastic products account for a large proportion. For instance, clothes hangers, plastic bowls, plastic water bottles, etc. If you want to turn your ideas into real plastic products, please contact us for the best solution.

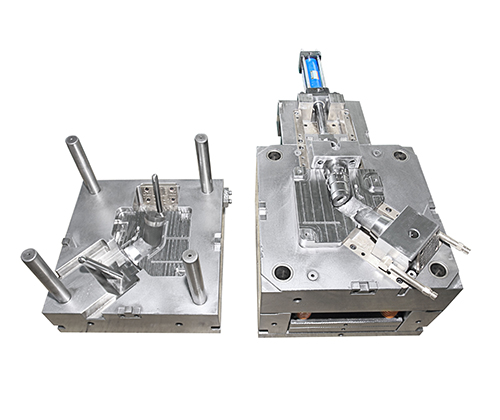

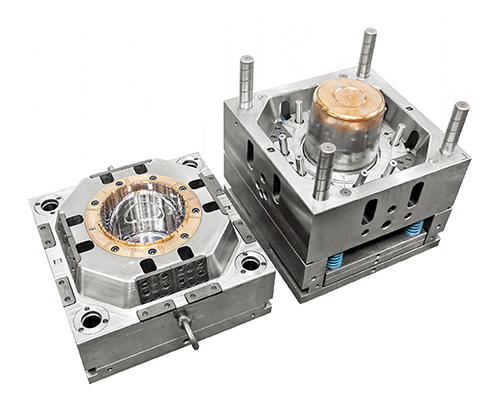

● PVC usually comes in two forms: the first is rigid PVC and the second is flexible PVC.

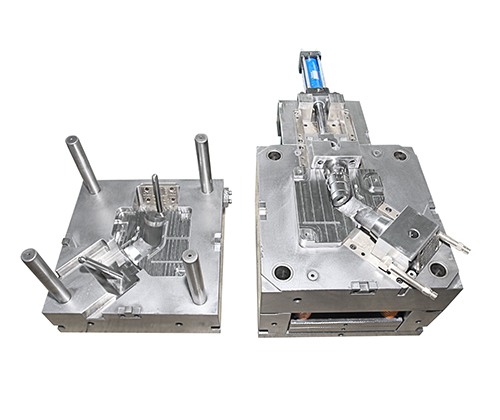

● In the field of injection molding machines, PVC molds usually refer to PVC pipe joint molds. The structure of such molds is often rather complex because they require the installation of cylinders on the molds to assist in molding. Conventional PVC products are widely used in the construction field.

● If you need to consult about PVC molds, please contact us to provide the best solution.

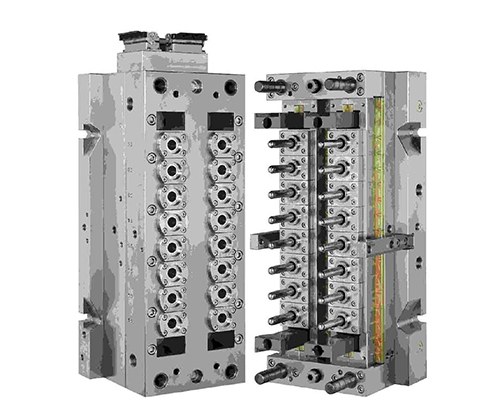

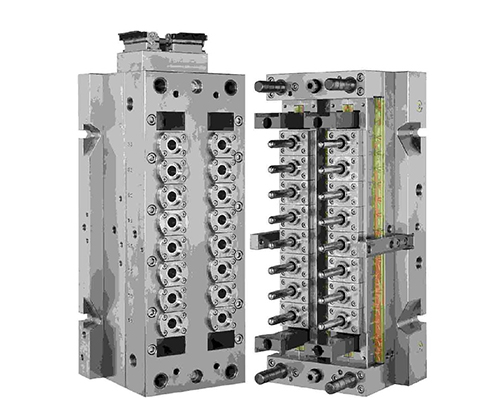

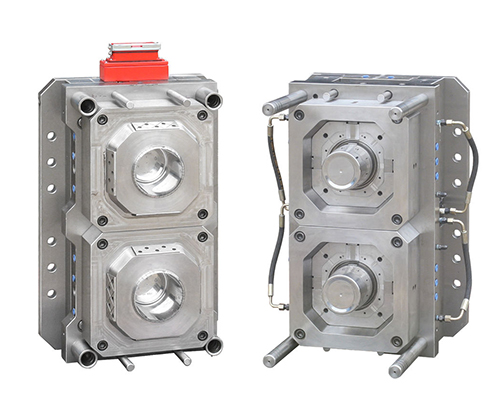

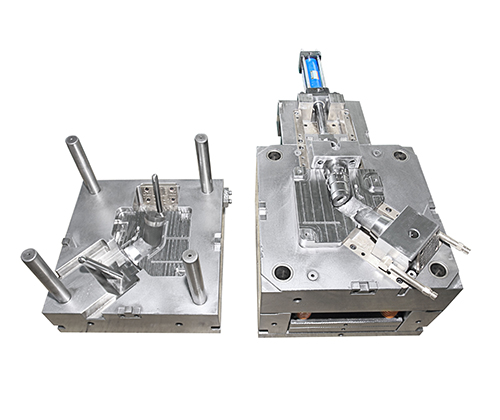

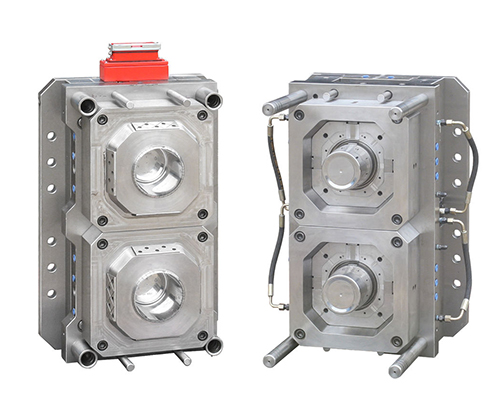

● A PET mold is a special mold used for making PET preforms. PET preforms are the first step in the production of plastic bottles. First of all, we produce "mini bottles" with threaded mouths, namely bottle preforms, through PET molds. The final bottle body shaping is completed through a bottle blowing machine. A good PET mold is extremely important for the final bottle body formation.

● Generally, the number of cavities in a PET mold is even, such as 8 cavities, 12 cavities, and so on. For those with high output requirements, it can even reach 64 cavities or more. The commonly available bottle mouth sizes on the market are 28mm, 30mm, 32mm and 38mm.

● If you need to consult about PET preform molds, please contact us to provide the best solution.

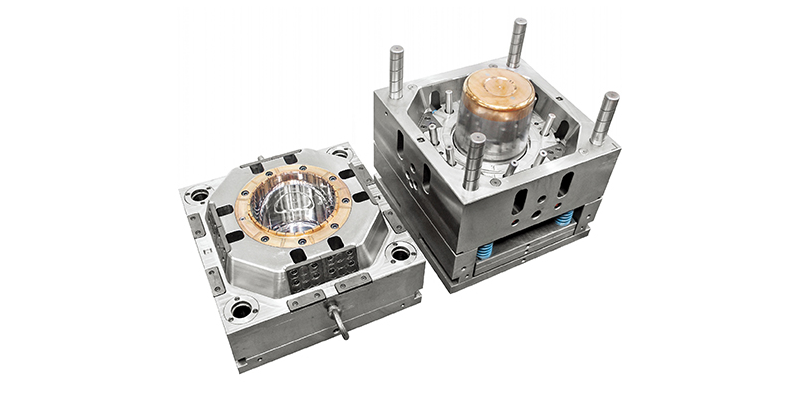

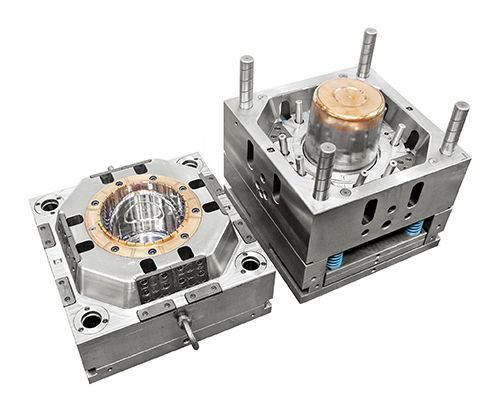

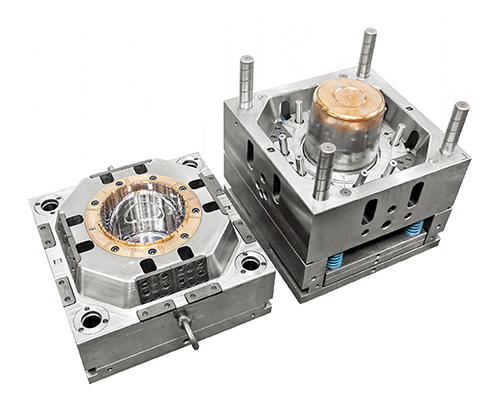

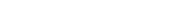

● Thin-walled molds are usually used to produce thin-walled products. The characteristics of this type of mold are that it saves raw materials and is highly efficient. In combination with high-speed injection molding machines, higher production efficiency can be achieved.

● In the field of injection molding, conventional thin-walled products include aviation cups, disposable fast food boxes and ice cream cups, etc. A well-designed thin-walled mold will greatly increase production efficiency and reduce the rate of defective products.

● If you need to consult about thin-walled molds, please contact us to provide the best solution